| Course Code |

Course Name |

Prerequisite |

Credit |

| MBN 101 |

Introduction to Materials Science and Nanotechnology Engineering |

Önkoşul: - |

(2-0) 2 |

| The importance of materials science, its historical development, and its role in technology. The development of metals, alloys, ceramics, polymers, and composite materials. Manufacturing methods used in materials science, fundamental material properties, and characterization techniques. The definition of nanotechnology and its place in contemporary technologies. General properties of nanomaterials. |

| MBN 201 |

Materials Science I |

Prerequisite: - |

(3-0) 3 |

| Classification of materials and their properties. Atomic theory and atomic bonding in solids; the structure of crystalline and non-crystalline materials, atomic coordination and ordering; crystal structure types; amorphous materials. Defects in solids: point, line, and surface defects. Mechanical properties: elasticity, plastic deformation, fracture, creep, and fatigue. Phase equilibrium; single- and two-component systems. Atomic movements and diffusion. Phase transformations: the concepts of driving force, nucleation, growth, and TTT curves. |

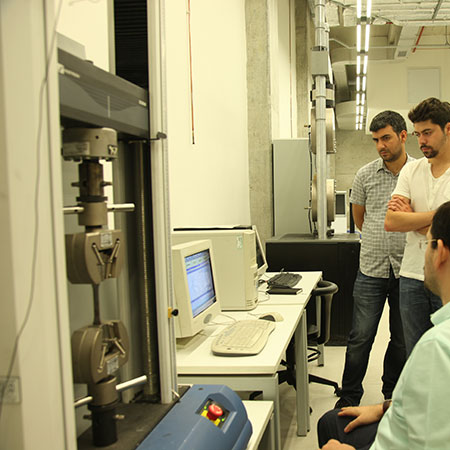

| MBN 201L |

Materials Science Lab |

Prerequisite: - |

(0-2) 1 |

| Material testing methods and the demonstration of certain fundamental phenomena, along with gaining practical laboratory experience in this field; specimen preparation for microstructural examination, sampling, mounting in resin, grinding, polishing, and etching, and examination under an optical microscope. Mechanical tests: tensile, hardness, torsion, fatigue, and impact tests. |

| MBN 202 |

Materials Science II |

Prerequisite: - |

(3-0) 3 |

| Covers the fundamental concepts that determine the optical, magnetic, electrical, and mechanical properties of metals, alloys, semiconductors, ceramics, and polymers. It also discusses how bonding, structure, and composition influence and control physical properties. Relationships among the processing–structure–property components are established. Within the scope of the course, electrical, thermal, magnetic, and optical properties are examined, and students are introduced to the application of these properties in practical contexts. In addition, metal corrosion and degradation in polymeric materials are also examined. |

| MBN 202L |

Materials Science Lab |

Prerequisite: - |

(0-2) 1 |

| This course is conducted in parallel with the Materials Science II (MBN202) course. In the laboratory sessions, practical applications are carried out to establish the relationships among the “processing–structure–property” components whose theory is taught concurrently. Within this framework, applications related to crystal structure, electrical conductivity in metals and semiconductors, the Hall effect, magnetism, optical properties, and corrosion are introduced to students. The course enables students to gain experience in observation, data collection and evaluation, and the reporting of scientific results. |

| MBN 203 |

Thermodynamics |

Prerequisite: - |

(3-0) 3 |

| The laws of thermodynamics. The concepts of internal energy, entropy, enthalpy, and heat capacity. The behavior of ideal gases. Heat engines. The Carnot cycle. Auxiliary thermodynamic functions. Gibbs and Helmholtz free energies. Materials thermodynamics required for the analysis of processes such as chemical reactions and phase transformations. Thermodynamics of ideal and non-ideal gas behavior. Fundamental concepts of solution thermodynamics. |

| MBN 206 |

Industrial Materials and Production Processes I |

Prerequisite: - |

(3-0) 3 |

| Introducing students to the processing methods of the most widely used metallic and ceramic materials in industry. |

| MBN 206L |

Industrial Materials and Production Processes Lab 1 |

Prerequisite: - |

(0-2) 1 |

| Carburization, vibratory, wet, and magnetic separation applications in metal production. Metal production by casting processes. Applications for improving the properties of metals. Ceramic production applications. Polymer production applications. Composite material production applications, including pressing and casting processes. |

| MBN 208 |

Chemical Theories in Nano Science and Engineering |

Prerequisite: - |

(3-0) 3 |

| Introducing students to the fundamental chemical theories underlying the synthesis and self-assembly processes of nanostructured materials, as well as the chemical theories that affect the performance of nanomaterials and devices; chemical interactions, thermodynamics of small-particle systems, diffusion, carbon-based materials, supramolecular chemistry, colloid and polymer chemistry, surface modifications, surface treatments, and catalysts. |

| MBN 212 |

Modern Physics |

Prerequisite: - |

(3-0) 3 |

| Special relativity and the historical development of modern physics. Blackbody radiation. The photoelectric effect and the Compton effect. The Bohr atomic model. The de Broglie hypothesis. The Schrödinger wave equation. An overview of quantum physics. |

| MBN 303 |

Transport Mechanisms |

Prerequisite: - |

(3-0) 3 |

| Types of transport phenomena and their measurement. Fluid flow, energy balances, friction, heat transfer, conduction, convection, radiation, mass transfer, homogeneous kinetics, diffusion, heterogeneous reactions, nucleation, and metastable products. |

| MBN 303L |

Transport Mechanisms Lab |

Prerequisite: - |

(0-2) 1 |

| Understanding and evaluating transport phenomena in materials production and processing, and modeling the fundamentals of transport mechanisms. |

| MBN 304 |

Nanomaterials and Production Methods |

Prerequisite: - |

(3-0) 3 |

| Within the scope of this course, the synthesis of nanomaterials using so-called bottom-up and top-down engineering approaches is presented. The techniques covered include photolithography, electron-beam lithography, nanoimprint lithography, chemical and physical vapor deposition, plasma and plasma etching, template synthesis methods, the sol–gel method, metal reduction methods, and emulsion polymerization. |

| MBN 305 |

Phase Transitions and Diagrams |

Prerequisite: - |

(3-0) 3 |

| The concept of equilibrium; phase, component, the Gibbs Phase Rule, and Le Chatelier’s Principle. Single-component systems: P–T diagrams, G–T diagrams, the Clausius–Clapeyron equation and its applications. Binary systems: solid solutions and the Hume–Rothery rules, isomorphous systems, the lever rule, phase analysis, G–X diagrams, reactions involving three-phase equilibrium (invariant reactions), eutectic reactions, phase analysis and examples, reactions involving three-phase equilibrium (invariant reactions), peritectic reactions, phase analysis and examples, formation of intermediate phases or compounds as a result of peritectic reactions, melting behavior of intermediate phases or compounds and solid-state phase transformations, ternary systems, the Gibbs triangle and composition determination methods, Alkemade’s theory, the liquidus surface, primary crystallization regions, composition triangles, and the melting behavior of compounds or intermediate phases. Applications of phase analysis during solidification. |

| MBN 307 |

Industrial Materials and Production Processes II |

Prerequisite: - |

(3-0) 3 |

| Introducing students to the processing methods of the most widely used polymer and composite materials in industry. An introduction to polymerization processes, including the examination of free-radical, suspension, emulsion, coordination, and step-growth polymerization methods, and the production of industrial polymers using these methods. Processing techniques for industrial polymers. Industrial polymers for specialized applications. Composite structures and industrial composites. |

| MBN 307L |

Industrial Materials and Production Processes Lab |

Prerequisite: - |

(0-2) 1 |

| Laboratory-scale production of engineering materials widely used in industry, particularly polymer and composite materials. Production of vinyl-based polymers through suspension, emulsion, solution, and bulk polymerization within the scope of free-radical polymerization. Production of polyester and Nylon 6,10 using the step-growth polymerization method. Production of a carbon fiber–based composite in a dish antenna geometry. |

| MBN 308 |

Mechanics of Materials |

Prerequisite: - |

(3-0) 3 |

| Elasticity and plasticity. Micromechanics of deformation, dislocations, and slip systems. Fundamental strengthening mechanisms: strain hardening, grain size strengthening, solid solution strengthening, and particle strengthening. Mechanical properties at high temperatures. Micromechanics of fracture: brittle fracture, void nucleation, growth, and coalescence. Ductile–brittle transition temperature. Fatigue and creep mechanisms in materials. Toughening mechanisms in materials. Mechanical properties of composites. |

| MBN 310 |

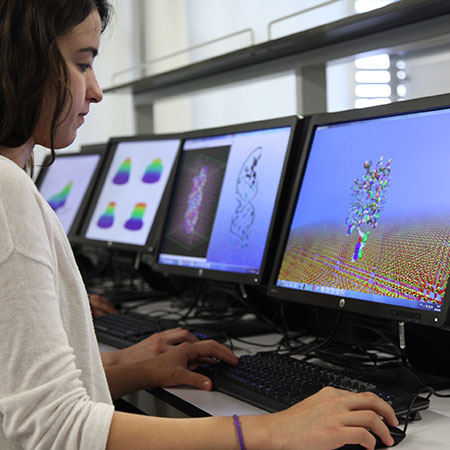

Computational Methods in Materials Science |

Prerequisite: - |

(3-0) 3 |

| Fundamental programming and algorithms. Roots of functions. Numerical solution methods for systems of linear equations: the Gauss elimination method, LU decomposition, and iterative methods. Matrix operations: determinant and matrix inverse calculations. Numerical integration methods: the trapezoidal, Simpson, and Romberg methods. Numerical solution methods for differential equations: the Euler and Runge–Kutta methods. Fourier transformations. Probability and statistical calculations. Linear regression and correlation. |

| MBN 312 |

Solid-state Physics |

Prerequisite: - |

(3-0) 3 |

| Within the scope of this course, the fundamental properties of solids and their application areas are introduced to students. Accordingly, students are first introduced to the meaning of solid-state physics and the basic approaches used in the classification of solids. Key topics such as lattice structures, lattice vibrations, and energy band theory, which form the basis of the electrical, thermal, magnetic, and optical properties of solids, are covered, and semiconductors and semiconductor devices with widespread modern applications are explained. Finally, dielectric properties and superconductors are introduced to students, and the course establishes a fundamental connection with nanostructures. |

| UGİ 315 |

Entrepreneurship and Leadership |

Prerequisite: - |

(2-0) 2 |

| Examinations and evaluations of the economic, legal, financial, behavioral, psychological, social, and cultural dimensions that emerge depending on different types of entrepreneurship, including intrapreneurship and small business/family business entrepreneurship. Leadership is addressed as both an individual and a social process through the dimensions of being, knowing, and doing (leadership theories, motivation, communication, team building, and creativity). The entrepreneur–leadership relationship and the factors influencing entrepreneurship are defined. Entrepreneurship is examined within its historical context through international and Turkish examples. |

| END 320 |

Engineering Economics |

Prerequisite: - |

(3-0) 3 |

| Economic analysis of engineering decisions: the time value of money, cash flow analysis, cost of capital, return on investment, costs and cost estimation, break-even analysis, decision-making among alternatives, the effect of depreciation, taxes, inflation, replacement analysis, and sensitivity analysis. |

| MBN 403 |

Nanoscale Characterization Methods |

Prerequisite: - |

(3-0) 3 |

| The most commonly used techniques in nanomaterial characterization are covered in detail in this course. The techniques discussed include nanocaracterization methods such as Auger, XRD, XRF, EDAX, UV–Vis, SPR, IR, Raman, NMR, DLS, viscometry, SEM, TEM, and AFM. |

| MBN 403L |

Nanoscale Characterization Methods Lab |

Prerequisite: - |

(0-2) 1 |

| Within the scope of this laboratory, some of the production methods and characterization techniques covered in the MBN 304 and 403 courses are presented to students through hands-on practice. The experiments conducted include the characterization of polymeric, metal oxide, or metal-containing nanomaterials produced using methods such as sol–gel, metal reduction, and photolithography, employing techniques such as AFM, DLS, Zeta Sizer, and UV–Vis. |

| MBN 454 |

Advanced Mathematics for Engineering |

Prerequisite: MAT 201 /MAT 202 |

(3-0) 3 |

| Coordinate systems and transformations between coordinate systems; line, surface, and volume integrals; the gradient, divergence, curl operators, and Stokes’ theorem; tensor algebra; applications of differential equations; applications of second-order differential equations; Lagrange equations; and Hamilton equations. |

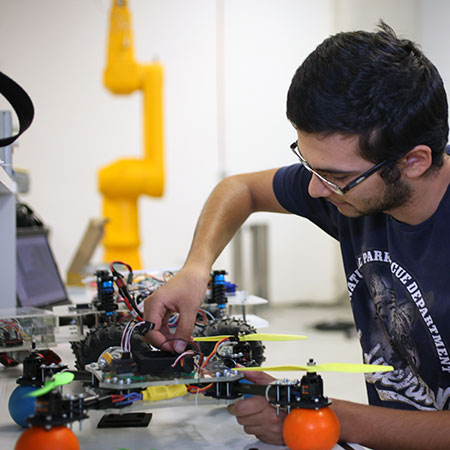

| MBN 497 |

Graduation Design Project |

Prerequisite: - |

(2-6) 4 |

| The course encompasses all stages from the selection to the completion of an industrially or academically appropriate project, aiming to provide materials science and nanotechnology engineering students with a comprehensive design experience by applying the knowledge and skills acquired during their undergraduate education. Within the scope of the course, students are expected to engage in collaborative work and to produce written reports and oral presentations. |