Research Topics

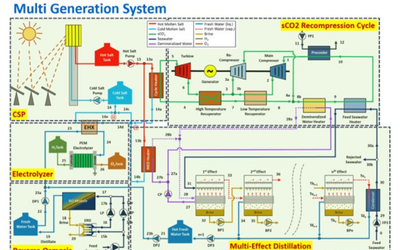

CSP and sCO₂ Based Multi-Generation System: Integration of Electricity, Fresh Water, and Green Hydrogen

This project aims to develop a fully sustainable multi-generation system for rural areas along the coastline, remote settlements, and islands. The system combines electricity generation, drinking water supply, and green hydrogen production into a single integrated platform. The sCO₂ (supercritical carbon dioxide) power cycle, powered by concentrated solar power (CSP), generates electricity with high efficiency, while the resulting waste heat is converted into fresh water via a MED (Multi-Effect Distillation) system; the surplus electricity is then used to produce green hydrogen via electrolysers. Thus, energy, water, and fuel needs are met with a single solution. In the system architecture, the heat obtained from CSP is transferred to the sCO₂ cycle via thermal storage. The electricity obtained from this cycle is first directed to critical loads, then to water production via the RO (Reverse Osmosis) system, and the excess power is allocated to hydrogen electrolysis. While waste heat is transferred to MED units, RO provides flexible production support. Operating modes vary depending on solar conditions; during high solar radiation in the daytime, electricity and water production take priority, with excess power allocated to hydrogen production, while thermal storage comes into play at night. The system design considers the CSP area, TES dimensions, sCO₂ cycle parameters, RO/MED capacities, electrolyzer selection, and hydrogen storage strategies. Performance indicators include electricity production efficiency and quantity, fresh water production capacity and specific energy consumption, hydrogen production rate, and integration efficiency. In this regard, the project offers a quiet, compact, low-emission, and fully integrated sustainable solution for islands and remote coastal areas.

- Dr. Öğr. Üyesi Emrah Gümüş

Industry 4.0, Smart Manufacturing & AI Applications

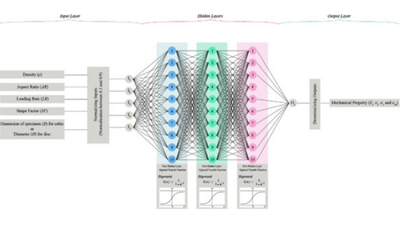

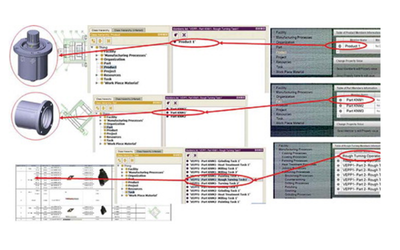

Real-time visibility, traceability, and online decision support are being enabled by integrating cyber-physical production systems with IoT, cloud, and edge computing. Lean-agile operations are being configured at scale through tight scheduling–CAPP integration, the simultaneous optimization of energy–time–cost, and human-centered dashboards. Interoperability is being reinforced via standards-compliant data models, APIs, and ontologies, while robust and extensible architectures are being established. On the AI side, explainable predictors of surface roughness, cutting forces, energy use, and failure likelihood are being developed under physics-informed constraints. Consequently, predictive maintenance, quality forecasting, and process-window optimization are being realized within digital-twin-enabled, data-driven lines, jointly improving efficiency, sustainability, and product quality.

- Dr. Öğr. Üyesi Bahram Lotfi

System Modelling & Analytics

Manufacturing systems are being represented end-to-end by combining discrete-event, continuous, and hybrid methods. Multi-objective formulations jointly capturing capacity, bottlenecks, energy, and cost are being constructed, and design/operations choices are being validated through simulation and digital twins. Uncertainties are being anticipated via scenario, sensitivity, and what-if analyses. Agent-based architectures are being designed for partner selection, collaborative planning, and distributed decision-making, while ontology-driven knowledge and rule management are being used to establish shared vocabularies and inference. By fusing experimental/field measurements with ERP–MES data, evidence-based, adaptive, and scalable analytics are being maintained, making decisions more transparent and improving operational performance and resource efficiency in an integrated manner.

- Dr. Öğr. Üyesi Bahram Lotfi

Manufacturing Technologies

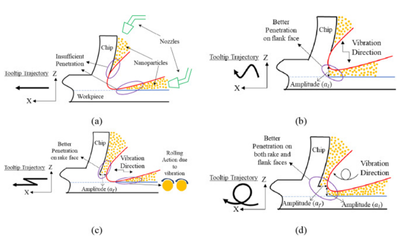

Hybrid strategies such as ultrasonic-assisted machining and minimum-quantity lubrication (MQL) are being advanced for the machining of advanced materials (e.g., Ti-6Al-4V, Inconel 718). Through these approaches, cutting forces and tool wear are being reduced while surface integrity and energy efficiency are being enhanced. Parameter-to-response relations are being resolved using design of experiments and data-driven models, and process windows are being optimized under quality, energy, and cost constraints. Along the CAPP–CAM–shop-floor chain, data integrity, online monitoring, and closed-loop control are being prioritized to ensure stable, repeatable performance. Within a sustainability perspective, the footprint of cooling-lubrication is being lowered, energy consumption is being reduced, and circularity is being strengthened through life-cycle-oriented solutions—thereby elevating product quality while meaningfully decreasing environmental impact and total cost.

- Dr. Öğr. Üyesi Bahram Lotfi

Development of Composite Armor for the National Combat Aircraft KAAN

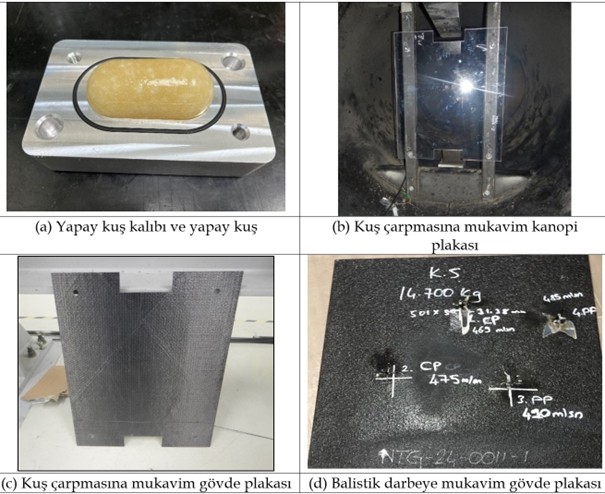

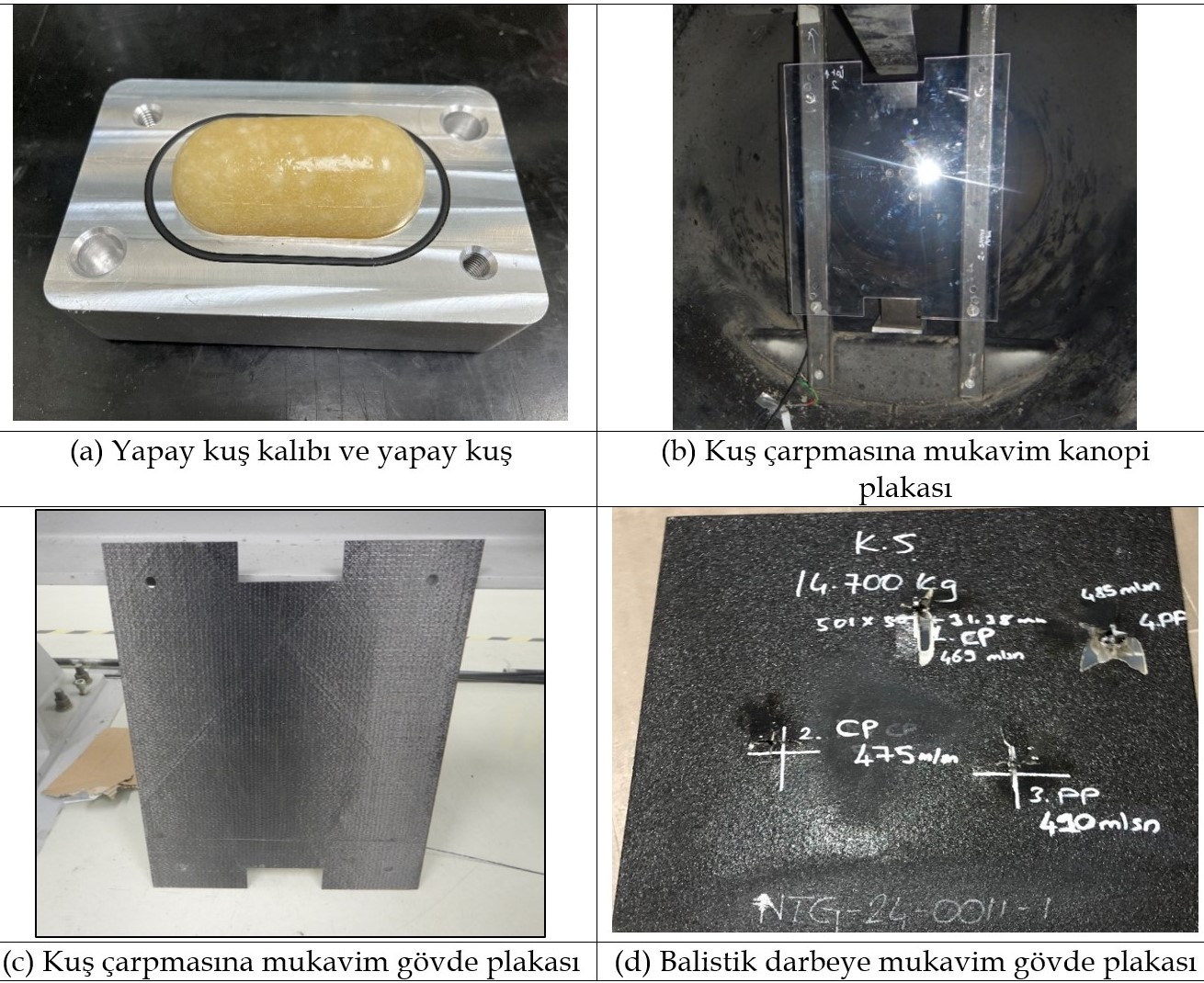

In this project, armor systems resistant to bird strike and ballistic impact threats were developed for both structural and transparent technology groups in compliance with international standards and optimized for mechanical and ballistic performance relative to weight. For the National Combat Aircraft KAAN, a multilayer aircraft canopy plate resistant to bird strikes was designed, and its performance was validated through bird strike tests. The canopy plates were manufactured by TUSAŞ, and the bird strike tests were conducted at Roketsan’s test center.

To support bird strike testing, a gelatin-based artificial bird formulation was developed. For the first time in Türkiye, artificial bird production was successfully carried out in a university laboratory (TOBB University of Economics and Technology, Department of Mechanical Engineering, Mechanics Laboratory).

Additionally, a multilayer armored composite fuselage plate resistant to both bird strike and ballistic impact was designed specifically for KAAN, and its performance was validated through bird strike and ballistic tests. The composite fuselage plates were manufactured by TUSAŞ; bird strike tests were performed at Roketsan, and ballistic tests were conducted at Nurol Teknoloji.

At the start of the project, the aircraft canopy and composite fuselage plates were validated at TRL 4. By the end of the project, the technology readiness level was advanced to TRL 6. The project resulted in publications in internationally reputable journals and presentations at national and international conferences. Doctoral, master’s, and undergraduate students involved in the project gained expertise in the testing, analysis, and optimal design of armored composites.

Funding Agency: TÜBİTAK (2021–2025)

- Prof. Dr. Erdem ACAR

Cellular (Porous) Solids

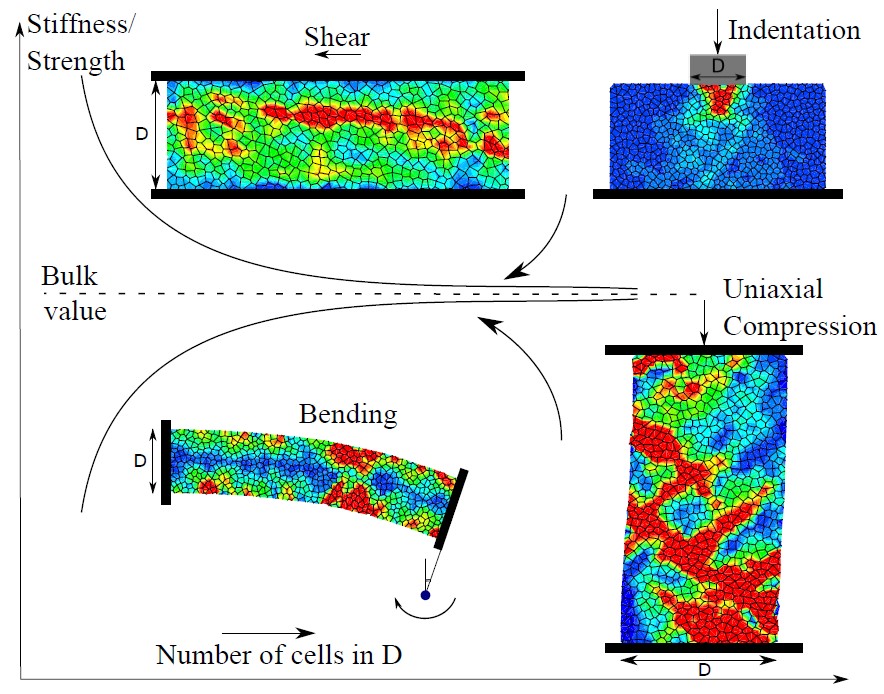

Cellular solids represent a relatively new class of engineering materials that, in addition to high strength and stiffness, offer great potential for structural applications due to their low density. While they provide superior macroscopic properties, an intriguing phenomenon emerges when one of the structural dimensions approaches the cell size: if the cellular solid consists of only a small number of cells, the cells no longer constrain each other’s movements and can deform relatively independently. This results in the mechanical properties becoming dependent on the specimen size.

In this context, finite element (FE) analyses were performed on model materials to investigate the mechanical behavior of cellular solids (see Figure 1). The FE results were compared with generalized continuum theories that incorporate a characteristic length scale to account for size effects. It was demonstrated that, within the elastic deformation regime, the best agreement was achieved with the theory that introduces “strain divergence” as an additional measure of deformation.

- Prof. Dr. Cihan TEKOĞLU

Design of Multifunctional Materials

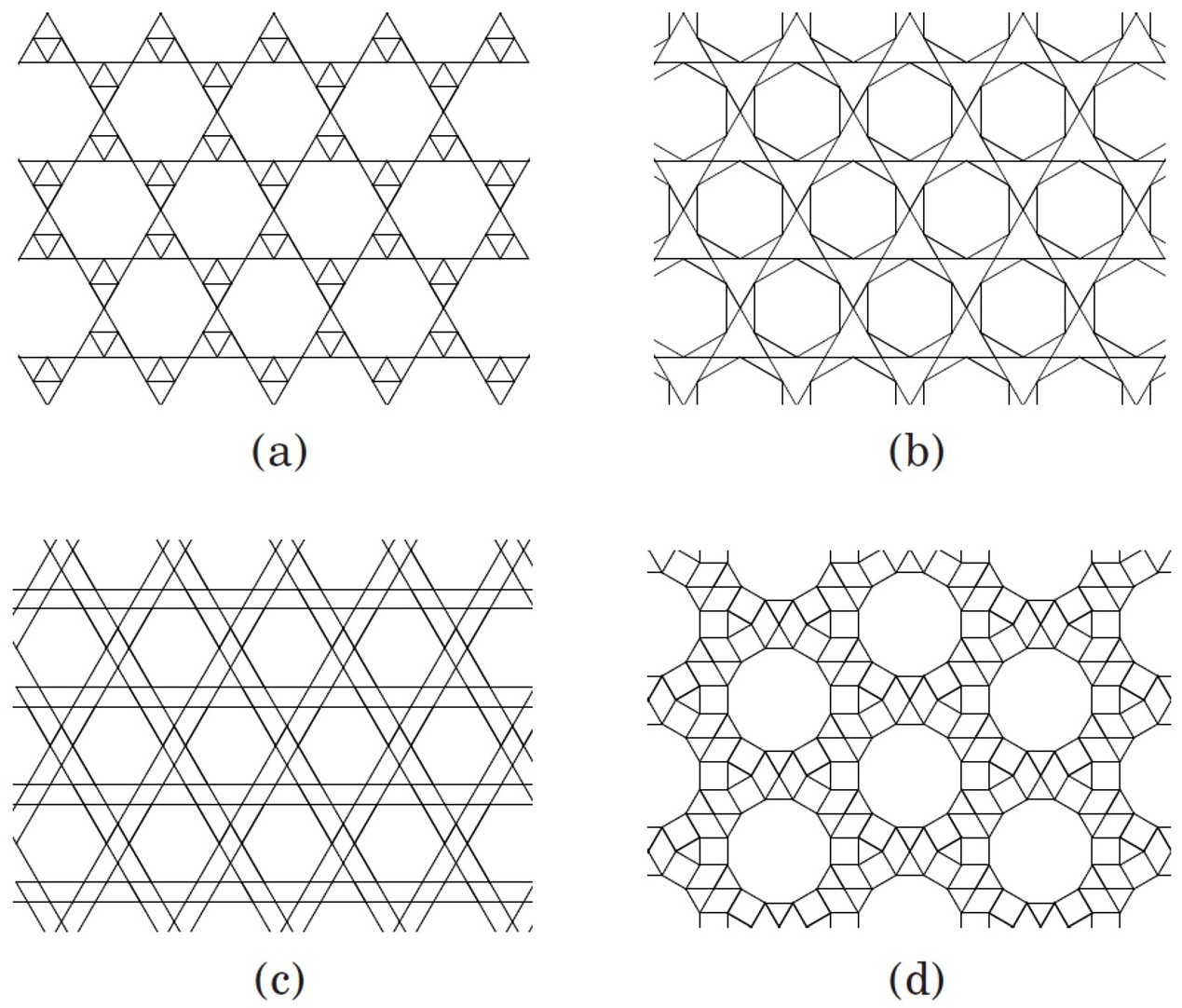

Another important research area concerns materials that combine mechanical functions (such as high stiffness and strength) with other properties (such as high thermal or electrical conductivity, or high deformability). Recent studies have shown that two-dimensional (2D) and three-dimensional (3D) Kagome lattice materials hold great promise for multifunctional applications. In such lattice structures, when certain struts are replaced with linear actuators, the material can deform easily through the extension and contraction of these actuators. When the actuators are inactive, however, the high stiffness is preserved, allowing the structure to maintain resistance against external loads.

The ability of the isotropic elastic Kagome lattice to exhibit both easy deformability and high stiffness raises two fundamental questions: (i) What makes a lattice material deformable with low energy input? (ii) Can lattice structures be designed that are even more favorable for deformation than the Kagome lattice? To address these questions, topological criteria were developed to identify micro-architectures favorable for deformation, and the symmetry requirements necessary for a lattice to possess isotropic elastic properties were established.

Within this framework, four new 2D in-plane isotropic materials were designed. Among them, the Double Kagome lattice (see Figure 2c) was found not only to possess optimal elastic properties but also to require less energy for deformation under actuator activation compared to the Kagome lattice.

Our research in the field of multifunctional materials has made significant progress through the development of numerous new lattice materials that exhibit not only isotropic elastic mechanical properties but also a negative Poisson’s ratio (NPR). NPR lattice materials offer several advantages, including high shear and indentation resistance, high energy absorption capacity, and enhanced toughness.

Potential application areas for these materials include fasteners and rivets, sensors, artificial blood vessels, bulletproof helmets and vests, smart textiles, and morphing aircraft wings.

- Prof. Dr. Cihan TEKOĞLU

MECHANIC

DEVELOPMENT OF COMPOSITE ARMOR FOR THE NATIONAL COMBAT AIRCRAFT KAAN

Project Leader: Prof. Dr. Erdem ACAR

In this project, armor systems resistant to bird strike and ballistic impact threats were developed for structural and transparent technology groups in compliance with international standards and optimized in terms of mechanical and ballistic performance relative to weight. Specifically for the National Combat Aircraft KAAN, a multilayer aircraft canopy plate resistant to bird strikes was designed, and the performance of the design was validated through bird strike tests. The aircraft canopy plates designed within the project were manufactured by TUSAŞ, while the bird strike tests were conducted at the Roketsan test center.

For use in bird strike tests, a formulation for the production of gelatin-based artificial birds was developed, and within the scope of the project, artificial bird production was carried out for the first time in Türkiye in a university laboratory (TOBB University of Economics and Technology, Department of Mechanical Engineering, Mechanics Laboratory).

Again, specifically for KAAN, a multilayer armored composite aircraft fuselage plate resistant to both bird strike and ballistic impact was designed, and the performance of the design was validated through bird strike and ballistic tests. The composite aircraft fuselage plates designed in the project were manufactured by TUSAŞ; bird strike tests were performed at the Roketsan test center, and ballistic tests were conducted at the Nurol Teknoloji test center.

At the beginning of the project, the aircraft canopy and composite fuselage plates were validated at TRL 4 through bench-top, component, and sub-component testing in a laboratory environment. By the end of the project, the technology readiness level was advanced to TRL 6. Based on the project outcomes, articles were published in internationally reputable journals, and papers were presented at national and international conferences. Doctoral, master’s, and undergraduate students involved in the project were trained in the testing, analysis, and optimal design of armored composites.

Funding Agency: TÜBİTAK (2021–2025)

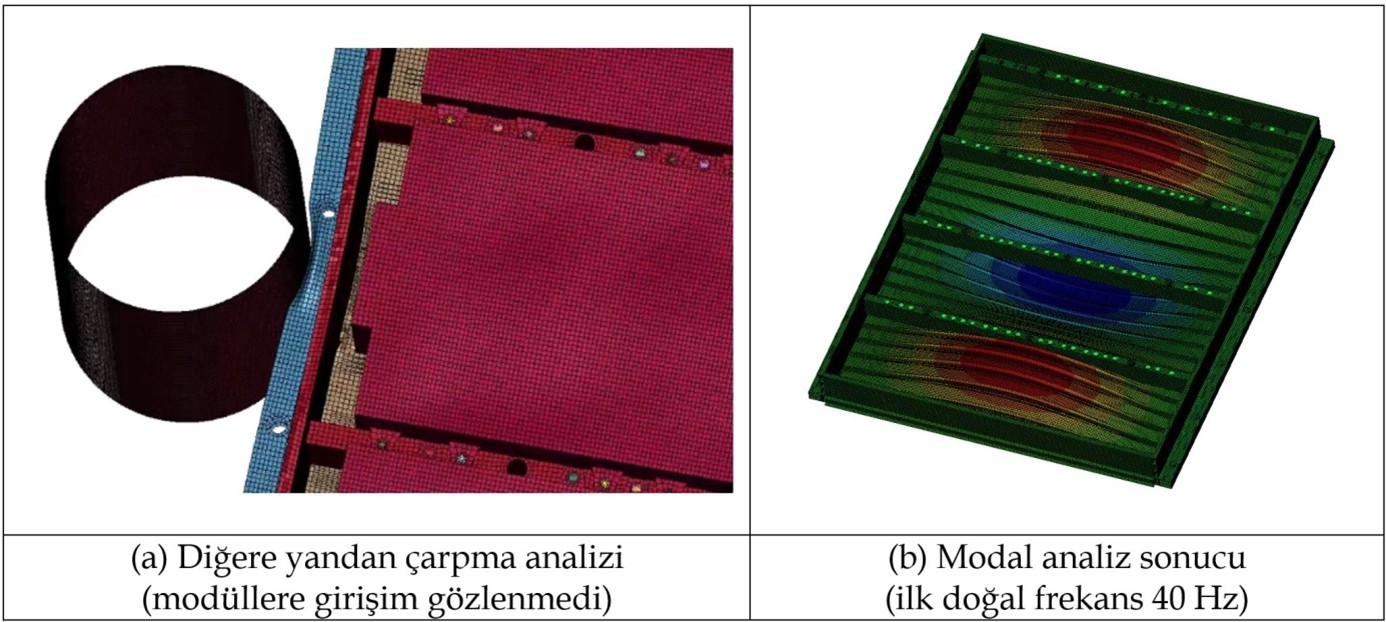

Development of a Composite Battery Carrier System for the National Electric Vehicle TOGG

This project aims to develop a composite carrier system for the batteries used in TOGG electric vehicles. R&D activities focus on the structural analyses and crash safety optimization of the battery carrier system. Within the scope of the project, fiber-reinforced composites will be investigated in terms of mechanical performance and dimensional stability.

The carrier system must ensure sufficient structural strength not only against instantaneous loads such as crash events but also against vibrational loads transmitted during driving. Therefore, its design will be carried out based on finite element simulations. Undoubtedly, carbon fiber is among the most effective reinforcement materials due to its superior specific mechanical properties. However, given its high cost, alternative reinforcement materials such as the more cost-effective glass fiber are also considered.

To determine the most suitable fiber type for the battery carrier system in terms of both cost and structural performance, the project also explores hybrid fiber solutions (a mixture of carbon and glass fibers). By using different proportions of carbon and glass fibers, the optimum carbon-to-glass fiber ratio will be determined.

At the beginning of the project, the battery carrier system was at TRL 2 (technology concept and application formulated). By the end of the project, the system is expected to reach TRL 6. Based on the project outcomes, articles are being published in internationally reputable journals, and papers are presented at national and international conferences.

Doctoral, master’s, and undergraduate students involved in the project are gaining expertise in the design, analysis, and testing of battery enclosures for electric vehicles.

Funding Agency: TÜBİTAK (2022–2026)

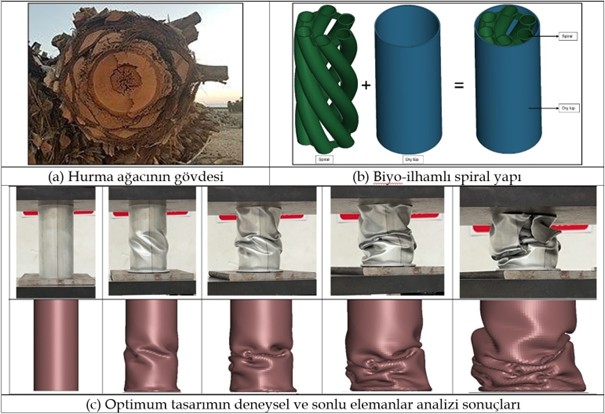

Development of a Bio-Inspired Hybrid Energy Absorber for Automobiles

In this project, the energy absorption performance of a bio-inspired hybrid energy absorber profile was investigated both experimentally and numerically. Inspired by the cross-sectional structure of a palm tree trunk, spiral inserts were placed inside a hollow aluminum tube to create the bio-inspired hybrid energy absorber. Spiral components and tensile test specimens were manufactured using metal-based additive manufacturing methods.

The bio-inspired hybrid energy absorber profile was subjected to axial crushing under quasi-static loading conditions. Simulation models created using ANSYS LS-DYNA finite element software were validated against the experimental results. Subsequently, optimization studies were carried out to further enhance the energy absorption performance of the bio-inspired hybrid profile.

Based on the project outcomes, articles were published in internationally reputable journals, and papers were presented at national and international conferences. Graduate students involved in the project gained valuable experience in the design, analysis, and testing of automotive energy absorption systems.

Funding Agency: TÜBİTAK (2023)

- Prof. Dr. Erdem ACAR

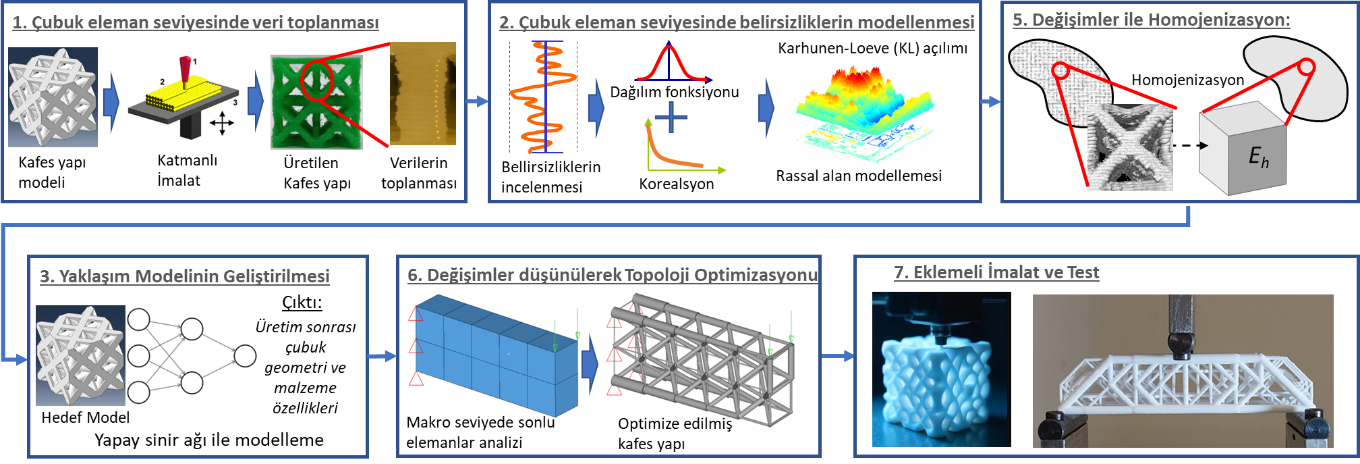

Design for Additive Manufacturing, Topology Optimization, Uncertainty Characterization, Artificial Intelligence

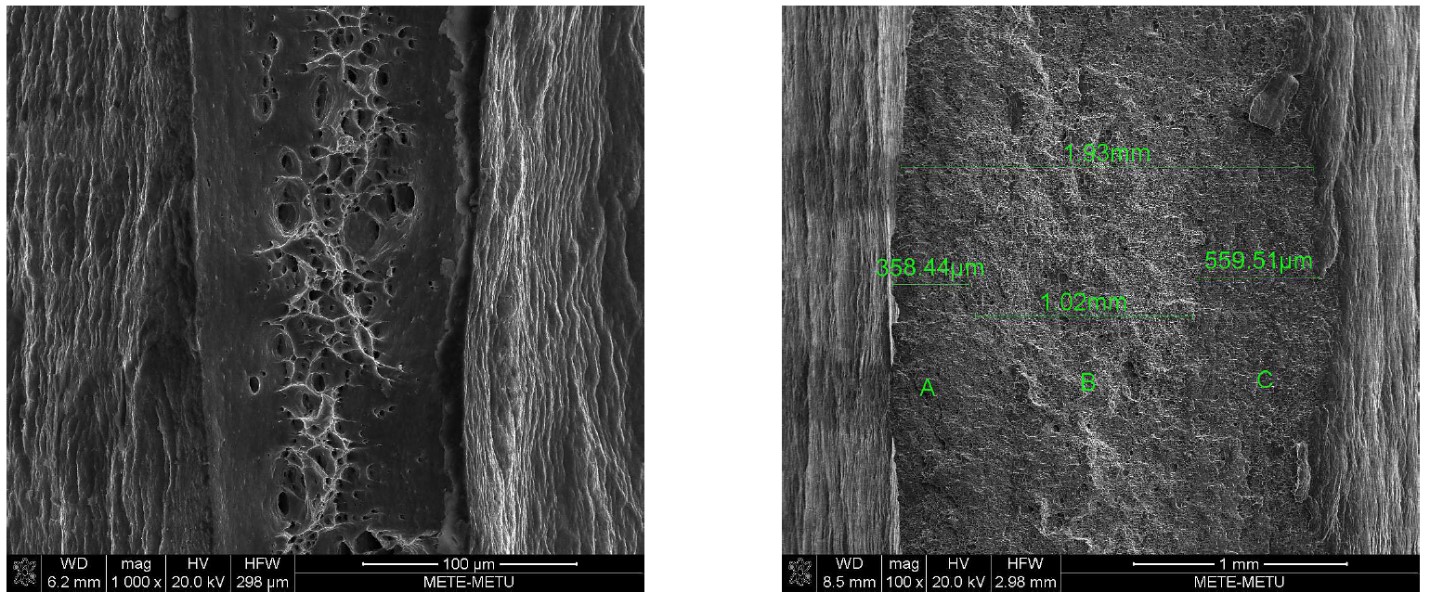

Additive manufacturing technologies are crucial for developing lightweight yet high-strength engineering components with their capability to produce porous and complex structures. Research conducted at our university focuses on lattice structures, particularly on understanding how geometric uncertainties that occur during additive manufacturing affect their mechanical performance. The uncertainties arising in additive manufacturing processes are characterized through micro-scale measurements (microscopy, micro-computed tomography, etc.) and incorporated into finite element analyses. In this context, integrating uncertainties into the design and optimization process plays a significant role. Accordingly, studies are carried out to include uncertainties in the optimization of lattice structures for high stiffness, aiming to minimize the effects of manufacturing-related uncertainties. As a result, high-performance and efficiently manufacturable lattice designs are developed.

In addition, research is conducted on the fracture mechanics of additively manufactured lattice structures. When lattice structures are produced by additive manufacturing, interlayer geometric uncertainties and defects can influence their fracture behavior. To address this, fracture tests on manufactured specimens are carried out within the university, and fracture analyses are performed using the Extended Finite Element Method (XFEM).

Furthermore, new lattice cell designs are being developed by considering factors such as the minimum manufacturable size and the capability of support-free fabrication in additive manufacturing. Whether these lattice cells exhibit isotropic properties is determined through homogenization methods. Lattice cells designed with isotropic behavior can then be used in the design optimization of engineering components through homogenization-based topology optimization. These research efforts are of particular importance for engineering applications in aerospace, automotive, and biomedical fields.

Topology optimization plays a central role in designing structures suitable for additive manufacturing. To improve the accuracy and efficiency of these optimization processes, artificial neural networks and deep learning techniques are employed. In this regard, convolutional encoder–decoder networks and transfer learning methods have been developed, enabling rapid and accurate predictions of optimization results. These approaches eliminate the need for iterative processes and significantly accelerate the optimization workflow.

Research on aluminum alloys and metal additive manufacturing focuses on structural optimization, durability, and production processes, which are especially critical for the aerospace sector. The production of lattice structures through metal additive manufacturing aims to design more efficient and robust structures by accounting for manufacturing errors and uncertainties. Moreover, these studies explore the potential of additive manufacturing for producing complex metallic geometries. In collaboration with industry, research particularly emphasizes the use of additively manufactured lattice materials in sandwich panels for aerospace applications. Through this approach, sandwich panels with lattice cores have been developed as alternatives to conventional honeycomb structures. The optimized designs are manufactured via metal additive manufacturing and experimentally validated.

Projects:

- Development of a Methodology for Effectively Accounting for Additive Manufacturing-Induced Variations in Lattice Structure Design via Optimization, TÜBİTAK 3501, 2019–2022.

- Determination of Structure–Property Relationships Based on Fracture Mechanics under Uncertainties from Material Extrusion in Lattice Structures, TÜBİTAK 1001, 2022–2025.

- Development of a Method for Designing Sandwich Aerospace Panels with Lattice Materials Considering Metal Additive Manufacturing Constraints, TUSAŞ, 2022–2025.

Relevant Courses:

- MAK 410: Finite Element Method for Mechanical Engineers

- MAK 420: Computer-Aided Design and Manufacturing

- MAK 408: Optimization Techniques and Applications in Mechanical Engineering

- MAK 512: Finite Element Analysis in Solid Mechanics

- MAK 520: Computer-Aided Design and Manufacturing (CAD/CAM)

- Assoc. Prof. Dr. Recep M. Görgülüarslan

- MAK 408: Optimization Techniques and Applications in Mechanical Engineering

- MAK 410: Finite Element Method for Mechanical Engineers

- MAK 420: Computer-Aided Design and Manufacturing

- MAK 512: Finite Element Analysis in Solid Mechanics

- MAK 520: Computer-Aided Design and Manufacturing (CAD/CAM)

Metamaterials

Evolutionary optimization has endowed natural materials with highly efficient mechanical properties. For example, wood possesses a specific strength comparable to that of the strongest steels, while the fracture toughness of bone is an order of magnitude higher than that of conventional engineering ceramics. Such superior mechanical properties do not primarily stem from the intrinsic excellence of the material constituents themselves, but rather from their spatial arrangement within the material—that is, the material’s micro-architecture.

Modern engineering applications often demand the coexistence of properties that are inherently difficult to combine—for instance, high ductility with high strength, or ease of deformation with strong resistance. Our research in the field of metamaterials aims to develop strategies that address these requirements. Below are some examples of ongoing studies within this scope.

- Prof. Dr. Cihan TEKOĞLU

Fracture of Metals and Composites

Advances in materials science and manufacturing technologies have made brittle fracture in metals and metal alloys a rare phenomenon, now limited to extreme conditions such as very high strain rates, very low temperatures, and/or excessive impurity segregation at grain boundaries. As a result, together with fatigue and corrosion, ductile fracture has become one of the most critical aspects of structural integrity assessments.

Over the past half century, significant scientific progress has been achieved in understanding all three stages of ductile fracture in metals and alloys—namely void nucleation, growth, and coalescence (see Figure 3). However, fully transferring these advances into material design and manufacturing remains a challenge, requiring a deeper understanding of fracture processes.

In this direction, our research group is working on extending existing ductile fracture models by incorporating:

- Matrix material anisotropy

- Physics-based void coalescence models

- Size-scale effects

- Non-proportional loading conditions, including cyclic loading

In summary, the primary goal of our research group is to design new materials and improve the mechanical performance of existing ones—ranging from cellular solids to metallic composites—in order to meet the demanding requirements of modern engineering applications.

Projects:

- Investigation of the Effects of Deformation Mechanisms on the Mechanical Properties of Lattice Materials

TÜBİTAK (123M856), 1002 – Rapid Support – A, 2023, Budget: 74,997 TL - Design of New Multifunctional Lattice Materials

TÜBİTAK (219M296), 1001 – Research, 2020 - Investigation of Crack Propagation Mechanisms in Ductile Metal Plates Using Numerical and Experimental Methods

TÜBİTAK (315M133), 1001 – Research, 2016, Budget: 376,552 TL - Optimization of Microstructure in Dual-Phase (DP) Steels

TÜBİTAK (111M664), 3501 – Career, 2012, Budget: 123,690 TL

- Prof. Dr. Cihan TEKOĞLU

Modeling, Control, Vibration, Automation, and Artificial Intelligence

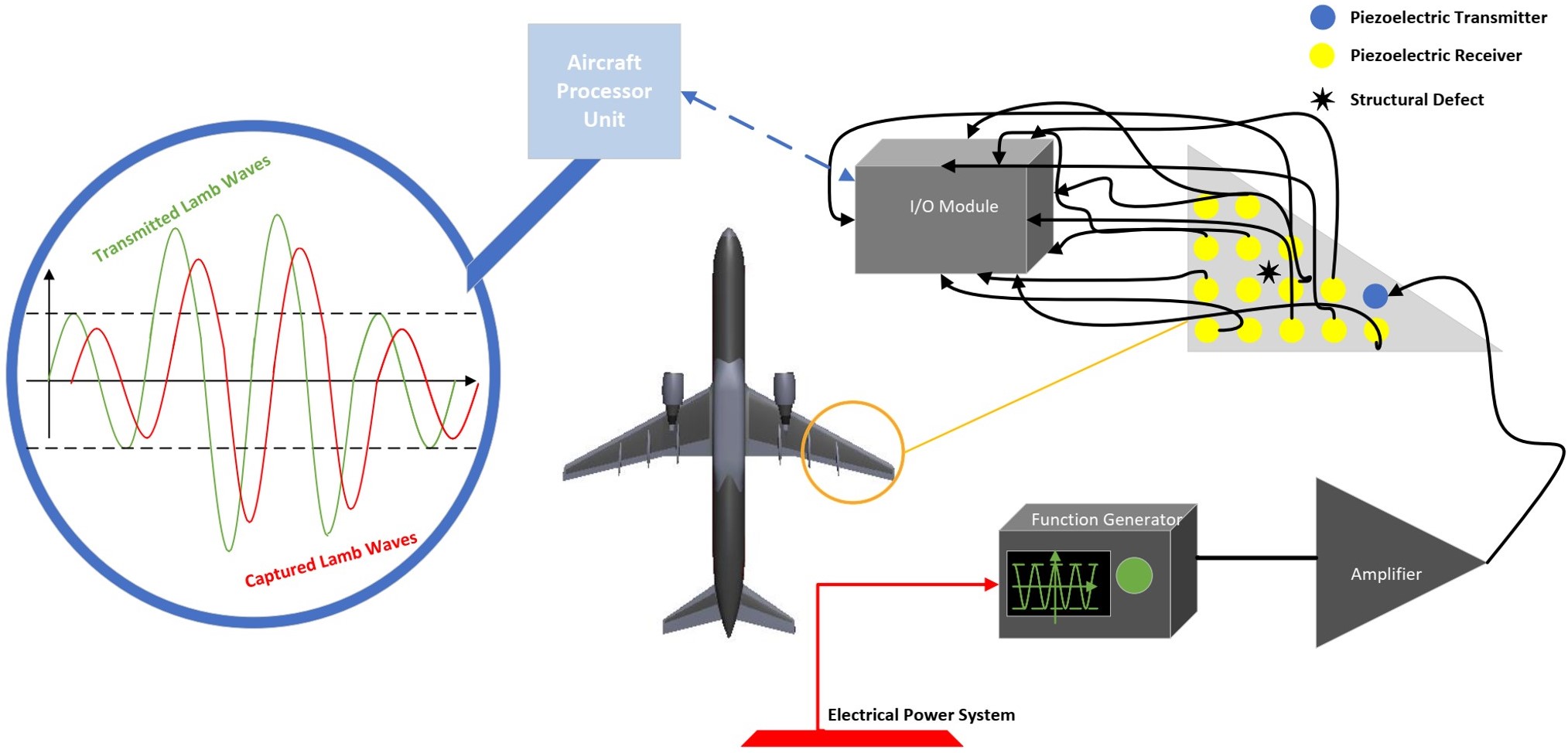

Modeling complex systems and developing control algorithms in mechanical engineering play a crucial role, particularly in aerospace and defense industry products. Recent advances in artificial intelligence—including data-driven system identification, machine learning, deep learning, and reinforcement learning—have found applications in structural health monitoring, model-based engineering and control, and digital twin technologies. At our university, R&D efforts in these areas continue through TÜBİTAK-supported projects and partnerships with leading industrial organizations in Turkey.

Selected Projects

- Development of Physics-Based Deep Learning Methods Supported by Smart Sensor Data for Structural Health Monitoring in Aircraft, TÜBİTAK-1001, 2023–2026

- Modeling Fatigue Performance of Aerospace Metal Alloys Using Machine Learning, TUSAŞ, 2022–2023

- Development of Deep Learning-Based Monitoring and Prediction Algorithms for Machining Processes in Industry 4.0, TÜBİTAK-1001, 2018–2021

Relevant Courses

MAK 305 – System Dynamics and Control

MAK 440 – Control System Design

MAK 441 – Mechanical Vibrations

MAK 449 – System Modeling and Dynamics

MAK 541 – Advanced Machine Vibrations

MAK 549 – Advanced System Dynamics and Control

- Prof. Dr. Hakki Özgür Ünver

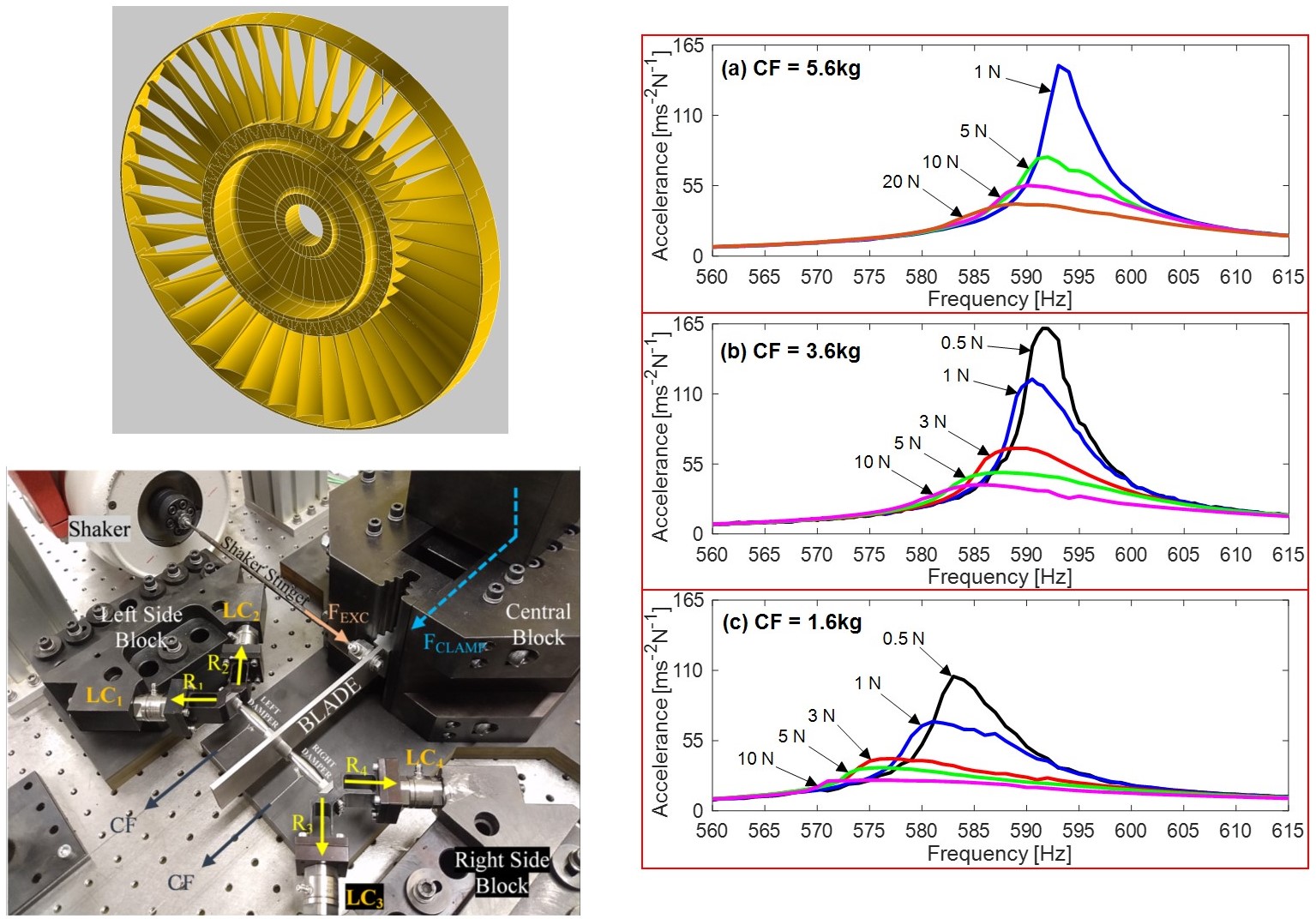

Structural Dynamics of Friction-Damped Turbine Blades

One of the most critical factors causing damage in gas and steam turbines is fatigue, which arises from oscillatory high stresses induced by mechanical vibrations in the turbine blades. Therefore, reducing high-amplitude vibrations is essential for the design of long-lasting turbines. One of the most widely used approaches to achieve this is to introduce intentional frictional contact in the blades, thereby providing energy dissipation within the system.

In our department, research in this area focuses on nonlinear vibration analysis and testing of bladed disks, uncertainty analysis and variability of system responses, and the development and validation of contact models. A related project has recently been approved by TÜBİTAK and is set to commence in the near future.

Selected Project:

Analysis of Nonlinear Vibration Response Variability in Friction-Damped Turbine Blades due to Non-Unique Residual Tractions: Model Development and Experimental Validation, TÜBİTAK 2232-B International Young Researchers Program, 2026–2029

Relevant Courses:

MAK 316 – Theory of Machines

MAK 310 – Numerical Methods

MAK 441 – Mechanical Vibrations

MAK 541 – Advanced Machine Vibrations

- Asst. Prof Dr. Erhan Ferhatoğlu

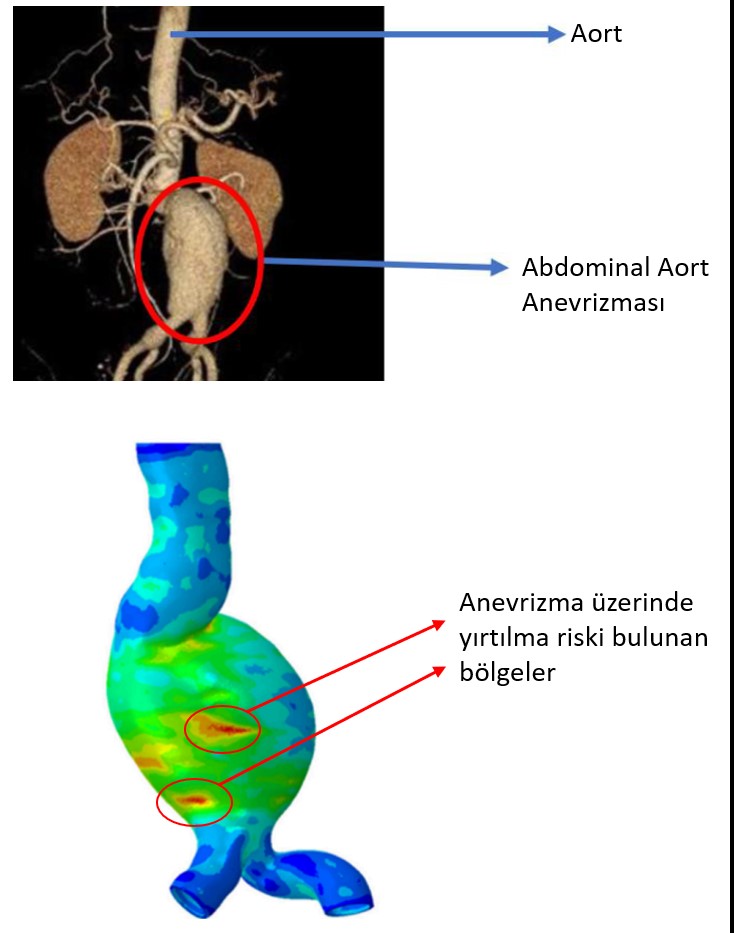

Stochastic Assessment of Rupture Risk in Abdominal Aortic Aneurysms

Abdominal aortic aneurysm (AAA) is a serious cardiovascular condition characterized by an abnormal enlargement of the abdominal segment of the aorta. Untreated AAAs carry a risk of rupture, which can be life-threatening. The normal abdominal aorta diameter is approximately 2 cm, and an AAA is typically diagnosed when the diameter reaches 3 cm or greater. While aneurysms can grow up to 9 cm over time, most cases are detected at around 5–6 cm.

In current clinical practice, an AAA with a diameter of 5.5 cm is considered high-risk, and surgical intervention is recommended. However, diameter alone is insufficient to accurately assess rupture risk. Rapidly expanding aneurysms (>1 cm/year), irregularly shaped geometries, or cases with high wall stress present a higher risk of rupture. In some instances, aneurysms with a diameter of 3 cm may rupture, whereas rarely, AAAs reaching 9 cm may remain intact.

Therefore, engineering and modeling studies are critical for more accurate rupture risk prediction and effective treatment planning. These studies examine the stress distribution within the aneurysm wall, helping to identify regions at higher risk of rupture.

Funding Agency: TÜBİTAK 3501 Career Program

- Assoc. Prof. Dr. Hüseyin Enes SALMAN