TOBB ETÜ's Students Came in the First in the World at the AIAA's Competition

9 YEAR(S) AGO

The students of the Department of Mechanical Engineering, TOBB ETÜ came in the first at the international competition held for the purpose of the design of an engine with a very high bypass ratio for Airbus A350, Airbus A380 and Boeing 787 airliners, the design and production of which is planned to be completed by 2025, with their design, titled ‘ETU-II-TTF’.

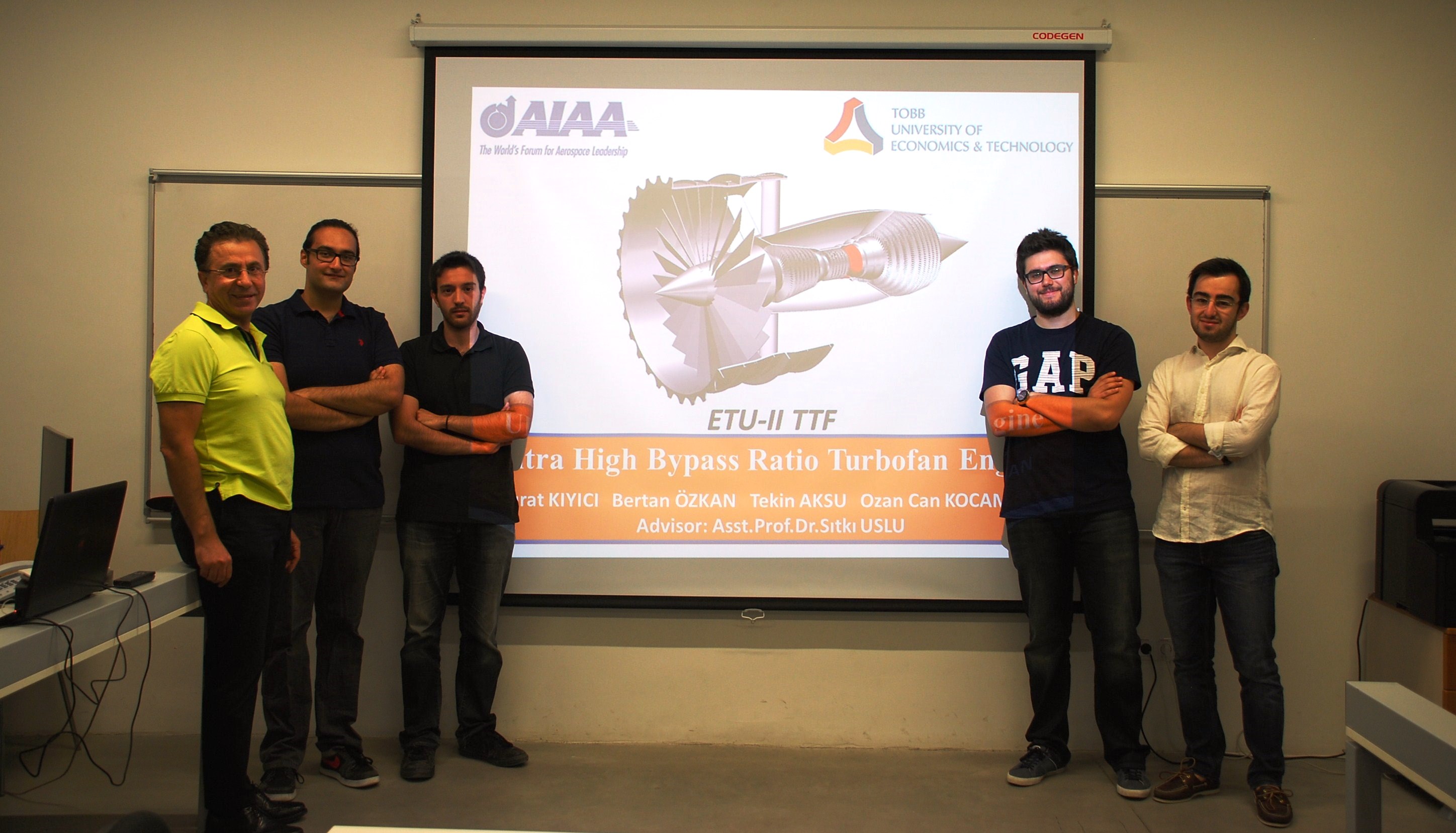

Fırat Kıyıcı, Bertan Özkan, Ozan Can Kocaman and Tekin Aksu, the students of the Department of Mechanical Engineering of our University, who worked on their design with the advisory of Assistant Prof. Dr. Sıtkı Uslu, achieved this brilliant success coming in the first at the international “Undergraduate Team Engine Design Competition 2015”, organized by the American Institute of Aeronautics and Astronautics-AIAA, being the most prestigious aviation institute in the world.

The final round of the competition was held during the “Propulsion & Energy Conference”, which was held in Orlando, Florida for the 51st time this year, and TOBB ETÜ's team was ranked the first, outscoring three teams from Embry Riddle University of the United States of America, the team of Kansas University as well as the team of Istanbul Technical University.

Assistant Prof. Dr. Sıtkı Uslu, a Faculty Member of the Department of the Mechanical Engineering, being the advisor of TOBB ETÜ's team, which prepared for the competition with the sponsorship support of our University and presented their design, provided the following information about the competition:

"The main objective of the competition was the design of a more efficient engine for the airliners, which are currently operated on flights and which have the minimum capacity of passengers. The primary design requirements of the competition were that the turbofan engine must be capable of performing satisfactorily at the altitude of 12 thousand meters, and also that such undesired engine parameters as engine fuel consumption, combustion emissions and noise must be optimized and reduced. The newly designed ‘ETU-II-TTF’ high by-pass ratio turbofan aircraft engine, which saves fuel by 16%, will consumer 21 tons of fuel less for a flight route of 22 hours.

Leveraging the experience we gained from our achievement at the last year's competition, at which we had come in third; this year, we focused more on the detailed design of the components of the engine, including the compressor, the combustion chamber, the turbine, the propelling nozzle and the computational fluid dynamics. We also developed designs, employing the computational fluid dynamics, for the cooling of the turbine blades (buckets= and the reverse propelling systems for landing. The students did not consider the project merely as a competition material but carried out the endeavor devotedly and with a great deal of focus, and also authored an international congress paper on the basis of the project."